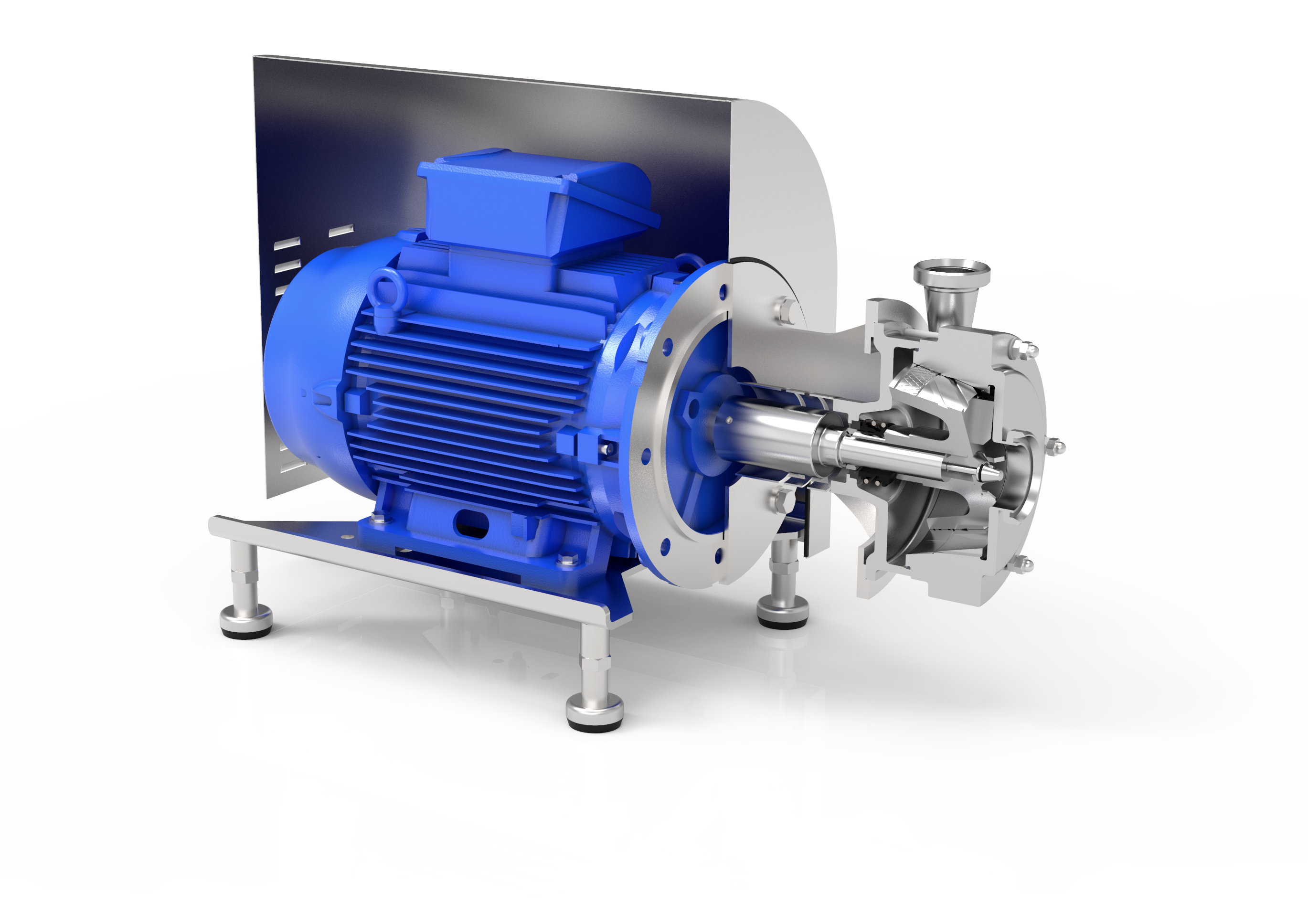

Specialist in hygienic mixing applications, Packo Pumps, has launched its colloid mill for the wet size reduction of solids in suspension and for pulping and mashing applications of bulky solids.

The Packo CM is a hygienic colloid mill is used in the production line in the food, fruit & vegetable and cosmetics industries. It has a toothed rotor and stator in electropolished duplex stainless steel and is used to precisely grind particles in suspension, with reproducible results in an annular gap between the stator and rotor which can be adjusted by changing the axial position of the rotor. The rotor and stator contain two milling zones and, because of the high shear forces between rotor and stator the CM will also mix the fluid.

The rotor with integrated centrifugal impeller improves suction capability and creates additional discharge pressure. The helicoidal grooves in the rotor guarantee quiet operation. All parts of the CM that come into contact with the product to be ground are in electropolished 316L or duplex and both motor and seals are standardised.