Two technologies, one from a micropump manufacturer and the other from a sensor solutions’ specialist, have been combined to develop a high-performance microfluidic driver. The system supports laboratory prototyping and product development in applications such as laboratory test systems, diagnostics, and analytical instruments.

Micropump manufacturer, TTP Ventus and Sensirion have collaborated to design a compact high-performance microfluidic driver. Together, the TTP Ventus Disc Pump and the Sensirion liquid flow sensor provide high levels of liquid flow control.

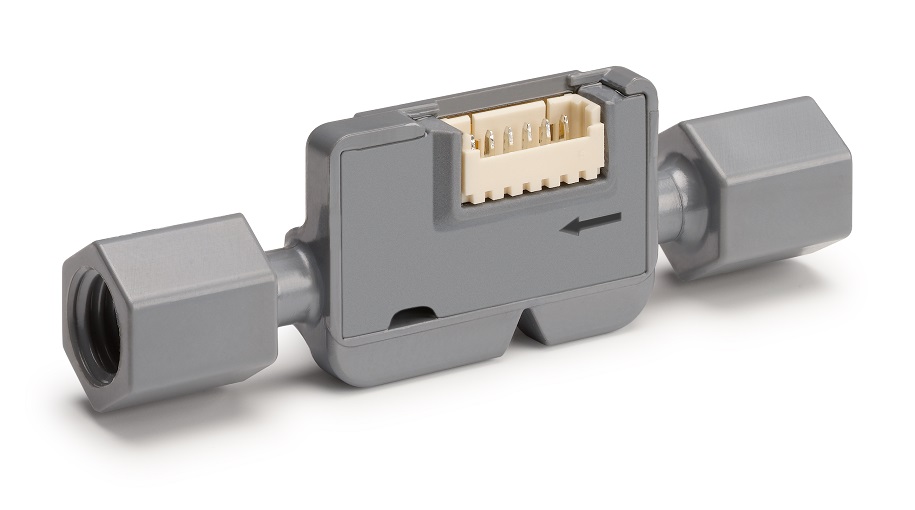

The companies have integrated Sensirion’s next-generation SLF3x series liquid flow sensor with TTP Ventus’ Disc Pump Evaluation Kit, taking advantage of the capabilities of each technology. The resulting stand-alone system provides a closed-loop, constant flow rate source for high-precision applications.

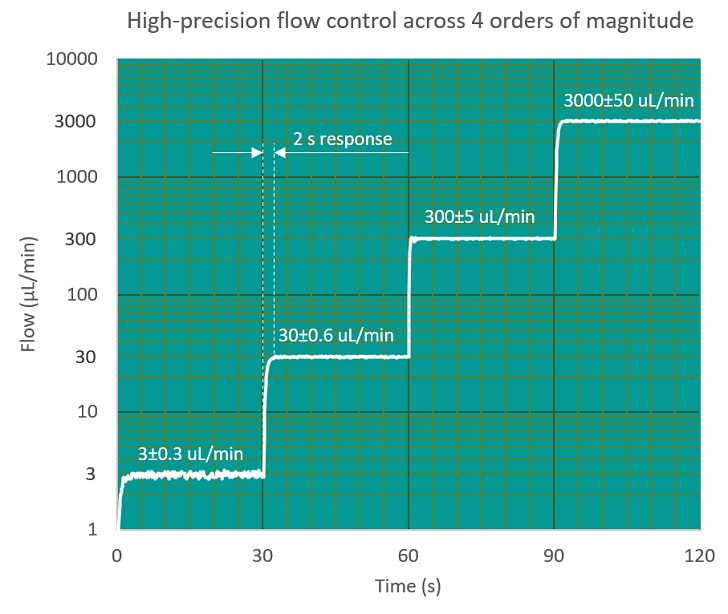

System features The key features of the system are a high-precision, stable flow-rate control, a large dynamic flow range with four orders of magnitude and smooth liquid flow with no pulsation or oscillation. The system also has a rapid response to setpoint changes and highly compact implementation is possible if required.

The system operates on a “pressure- driven flow” or “air over liquid” principle, where gas pressure generated by the pump is used to drive liquid flow through the microfluidic circuit. If cross- contamination between liquids must be avoided, Sensirion’s LD20 single-use sensor can be used instead of the SLF3x sensor series. This separation of the pump from the liquid supports the reusable-consumable model widely adopted in diagnostic and analytical instrumentation, with the pump located in a reusable part of the system and the liquid path and sensor in a consumable part.

Smooth liquid flow The micropump’s pulsation-free pressure generation delivers smooth liquid flow with none of the oscillation often seen with conventional technologies, such as peristaltic pumps. This brings several benefits, including the ability to create laminar flow, reduction of measurement noise and gentle handling of delicate materials. The pump also provides excellent pressure control which, together with the high-resolution capability of the sensor, results in high levels of liquid flow control.

The maximum flow rate that can be achieved is determined by the maximum pneumatic pressure the pump can deliver. Also a range of other factors including the liquid flow resistance through the system (e.g. as determined by the channel geometry and surface properties), the viscosity and surface tension of the fluid.

The minimum flow rate, in principle, should be zero, as the disc pump has no stall speed and therefore has a near- infinite turn-down ratio. The resolution of the pump output is also ‘continuous’. In practice, both the minimum flow rate and flow rate resolution are likely to be determined by the limits of the flow sensor and the pump drive electronics, rather than by the pump itself.

Wide dynamic range Both technologies offer a wide dynamic range, enabl- ing flow control over several orders of magnitude, from microlitres a minute (μl/min), to several millilitres per minute (ml/min), providing full flexibility when designing flow control protocols.

The closed-loop flow regulation enables the system to respond to full-scale set point changes in just a few seconds, enabling protocols to be sped up, and minimising wastage of precious or expensive materials.

Tom Harrison, chief commercial officer at TTP Ventus, commented: “With this collaboration, we wanted to show what is possible by combining TTP Ventus and Sensirion technology. We’ve demonstrated exceptional flow control with components small enough to be integrated into portable point-of-care devices.”

Susanne Pianezzi, product manager, Liquid Flow Products at Sensirion, went on to comment: “We hope the system we’ve created will provide a platform for product development and prototyping across the life science and industrial sectors, supporting the creation of a new generation of microfluidics devices.”